Wuux Going On…

Words: Dave Swan

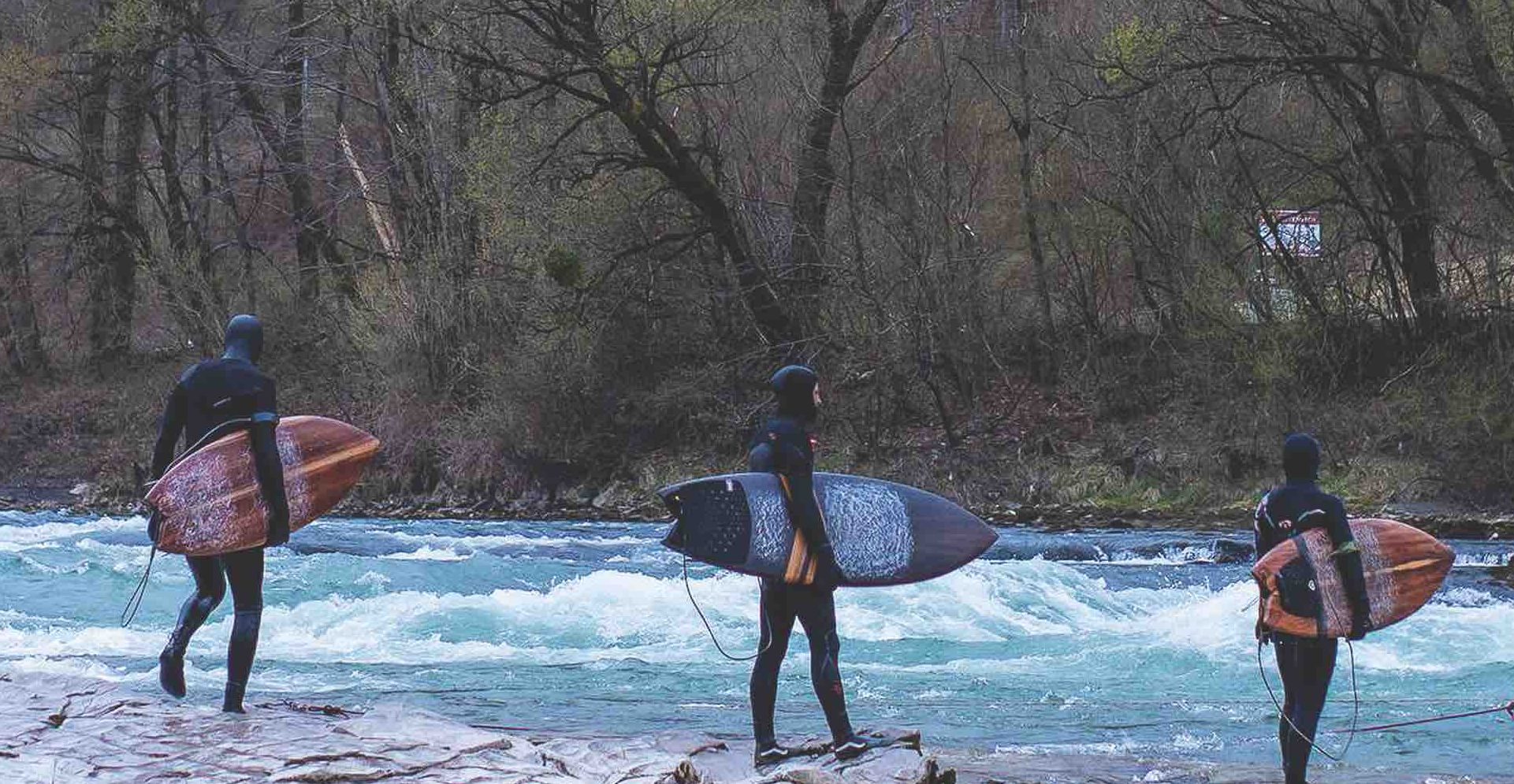

Photos: Wuux Surfboards

Being our Winter edition and in the pursuit of all things alpine, you sometimes come across some weird and wonderful things. This is most definitely on the wonderful side of things. May we introduce our readers to qualified architect and third generation woodworking artisan, Wilhelm Margreiter, from where “the hills are alive with the sound of music” (couldn’t resist sorry). Yes, Wilhelm is from Salzburg, Austria and this is the story of Wuux Surfboards.

Wilhelm’s wooden joinery business itself was originally founded by his grandfather in the 1950s and later passed on to his dad. They were famed for building snow skis, sledges (commonly known as sleds or sleighs to us) and furniture – the kind of craft you would expect to emanate from a land-locked country like Austria with no sea in sight. Anyhow, the spirit and enthusiasm of building sports equipment was well and truly there.

When Wilhelm later took over the business from his father he was approached by some crew to make surfboards for local river waves like the Eisbach in Munich (which is a man-made wave on the 2km-long river of the same name in Munich) he readily accepted the challenge with vigour.

Wuux Surfboards feature a multilayer foam core Wilhelm and his crew make themselves with a ‘full wooden jacket’. The nose and tail are additionally reinforced. Said Wilhelm, “All our products are handmade in our workshop in Grödig, Austria. Every step, from the construction of the core to the final sanding is done on-site. Also, unlike conventional glassing, the exact amount of resin is calculated for every Wuux surfboard – saving more waste. We are very environmentally conscious.

“We use high quality materials and a sophisticated construction to get long-lasting surfboards with less maintenance. We buy all our materials from local partners – reducing long transportation times to our workshop. We produce the core ourselves in the workshop. The left-over materials are used by a partner company as insulating materials. And as I said earlier, we use the exact calculated amount of epoxy resin – no resin on the floor, no waste.

“We try to improve our processes constantly to be more sustainable and environmentally friendly. We love upcycling. No matter if it is the fins, which consist of upcycled materials from the surfboard production, we try to give every piece of unused material another purpose. We even undertake consistent waste separation and use as little packaging as possible – no packaging if you buy at our shop.”

Reportedly, due to the unique construction, the Wuux surfboards are easy to repair and in keeping with their environmental ethos the residual material from surfboard production gets upcycled into Wuux Fins.

“In 2019 we invented a special technique for floating fins to reduce our waste and give the left-over materials a renewed purpose. This project was given financial support for prototyping by the Austrian Wirtschaftsservice – AWS.

“If you lose a fin, it is easy to collect it again because they swim – this is an advantage for surfers and nature! Our fin base is made of carbon and gives the fin stiffness and extra pop. The wood look and feel makes the fins not only perform but also look good, like unique little design pieces!”

Thanks to the foam core, Wuux Surfboards are very light compared to your standard wooden surfboards and approximately as light as a PU Surfboard. For example, their 9’4“ Wuux Wahoo (Longboard) is about 6.2 – 6.5 kg.

Each custom board takes around 6-8 weeks to build from scratch and retails from about $950 Euro ($1540 AUD). In terms of the wood used in all Wuux Surfboards, well, there are over 30 different varieties to choose from.

Wilhelm ships his boards and fins all around the world but if you happen to be in Austria, you might like to check out his showroom in Salzberg at Schützenstraße 12 5082 Grödig. There, Wilhelm has a range of boards on display as well rentals/test boards, 12 different types of centre trailers (a centre fin in a thruster setup specially designed for river surfing), pads, leashes, boardbags, surfboard tools, board racks and accessories. Indeed, the boardbags are made in a community project Wilhelm started with a local surfer, who makes each of them by hand right there in Salzburg and another local surfer is producing the patches, which Wilhelm designed, made of vegan leather. Wilhelm even has a surfboard repair service.